China EPS Machine supplier, factory - Longwell EPS Machine

Looking for China EPS Machine supplier, factory, you can choose Longwell EPS mold, a professional EPS Machine. China EPS Machines are sold all over the country. Welcome to contact us for cooperation.

About China EPS Machine

Longwell EPS Machine is to expand EPS raw material to required density, the machine works in a continuous way both in taking raw material and discharging expanded material.

Longwell EPS Machine can do second and third expansion to get low density.

Machine complete with Screw Conveyor, First and second expansion loader, Expander, Fluidized bed Drier

Application of China EPS Machine

The fat barrel, outside an all-stainless steel compartment, has insulation measures, reliable performance, reasonable structure, beautiful, stable quality, high production efficiency, increase 2-3 times than the average machine, low energy consumption 25%.

The machine feed system including a feeding device and the second feeding device, a feeding device by adjusting the feed rate of transmission in order to ensure a stable feed.

EPS beads through the material, the foam into the fluidized bed dryer ( customer optional ), and then into the aging silo through the fan delivery device, complete raw foaming process, process cycle according to the second foam.

The EPS Machine produced a more uniform density can foam density of 7-35kg/m3.

Let the steam valve, the user can choose according to need.

Looking for China EPS Machine supplier, factory, you can choose Longwell EPS mold, a professional EPS Machine. China EPS Machines are sold all over the country. Welcome to contact us for cooperation.

What are the functions of the EPS machine?

Simple EPS machine functions:

1. There are various production methods of the foaming EPS machine, which can be fully automatic, semi-automatic, intermediate start and manual operation.

2. The use of hydraulic system, so the EPS machine runs stably, with low noise and large clamping force.

3. The vacuum system of the EPS machine can speed up the molding speed of the product, shorten the cooling time and reduce the moisture content of the product.

4. The EPS machine has been optimized, and the redundant design makes the machine simple and clear, high in strength and cost-effective.

5. The EPS machine has a variety of heating, cooling, filling, product demoulding and other processes to adapt to the production of different EPS products.

6. Improve the EPS machine fault self-diagnosis and motor protection system to ensure the safe operation and protection of the equipment.

7. The simple foaming EPS machine is welded with high-quality steel plates, and after aging heat treatment, the machine has high strength, no deformation, and can withstand the expansion force of high-density products.

What are the precautions for the daily operation of the EPS machine?

EPS machine is a kind of equipment commonly used in foam production. Different types of EPS machines have different functions and functions, which can meet the needs of different production environments in factories. EPS machines are more professional equipment, so they are also It requires operators with relevant experience and skills. Many people don’t know much about this. According to the situation in this regard, let’s talk about the daily operation precautions of the EPS machine. .

EPS machine operation process

When using an EPS machine, you should first pay attention to the power supply used by the equipment and whether it can carry the load of the electric power. Secondly, you must confirm that the power supply is turned on and there is no safety hazard, and then confirm whether the equipment can operate normally. Avoid defective products in the products it produces, and at the same time, strictly abide by its operating system when operating.

Precautions for EPS machine operation

Because the EPS machine has a certain operating technology, during the operation, remember not to reach into the transmission position or the material box. This will easily cause the arm to burn, and during the operation, it is also To prevent additional materials from falling into the production line, these problems are likely to have greater safety hazards. During the normal operation of the equipment, the disassembly of the equipment should also be avoided, and the power supply should be cut off in time after the operation is completed.

The above is the introduction to the daily operation precautions of the EPS machine. I hope that the above introduction to the EPS machine equipment can bring people effective information and help. For the operation of the EPS machine, there are still many places that need to formulate an operating system.

About great EPS machine manufacturer:

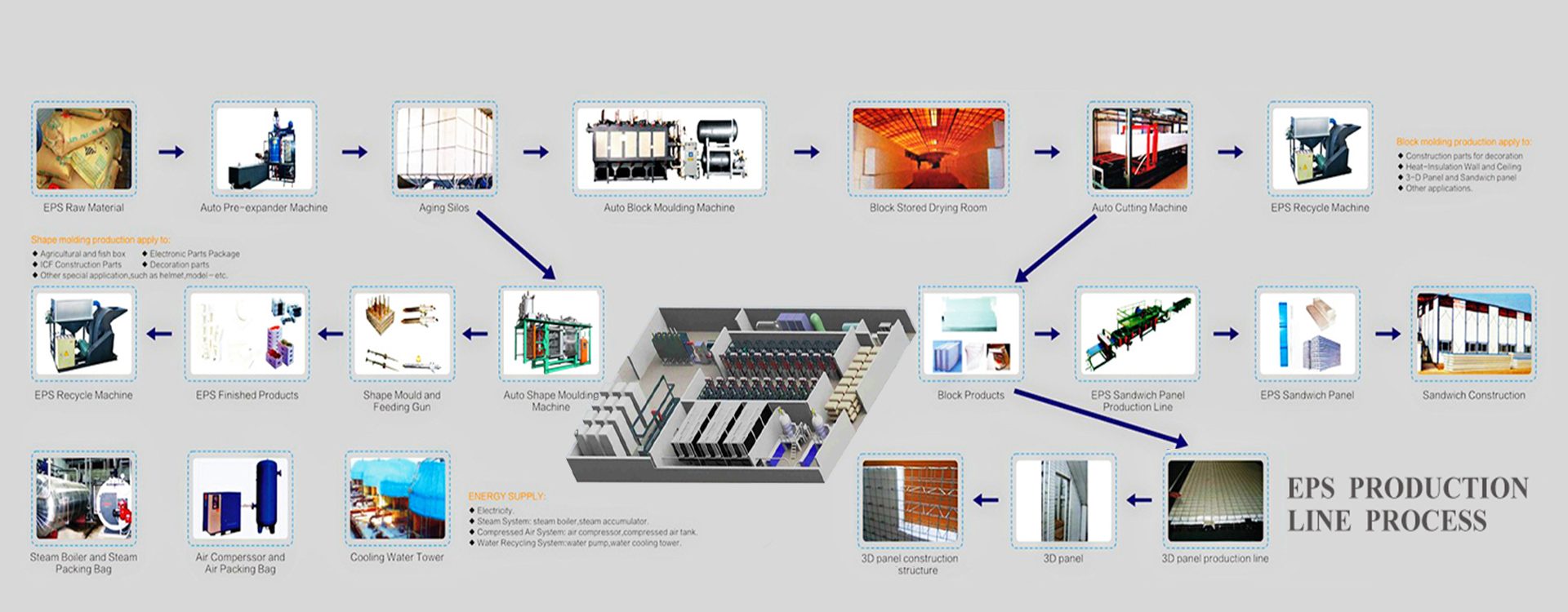

China Longwell is a professional EPS Machinery Supplier and polystyrene machine manufacturer, We offer kinds of EPS machines, EPS molds, 3D panel machines, sandwich panel machines, assistant facilities and all kinds of EPS machine spare parts.

For more product information about YouTube information of EPS machine manufacturers, you can click on the relevant link below.

Hangzhou Fuyang Longwell Industry Co.,Ltd