Temperature -- an important factor that can't be ignored for expanded process in winter

In autumn and winter, the temperature is low, and the EPS production process is sensitive to the temperature. Recently, many clients reported that there were problems with many raw materials, because they used to be very light. Now they do it according to the previous parameter method, the board is heavy, cracked, shrunk, etc. And this situation is relatively common. So the temperature is generally low in winter. What is the reason for this phenomenon? Is there really a problem with the raw materials? Or something else? What is the essence of this?

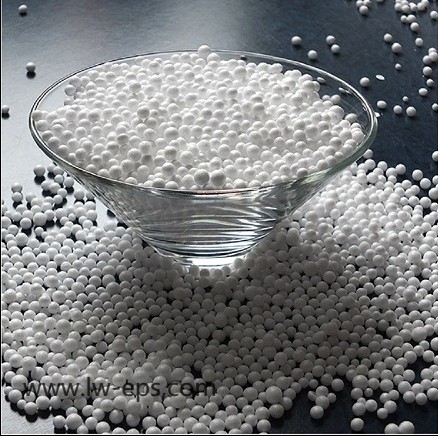

The temperature of the foam beads just sent out from the pre expander machine is generally between 40 ~ 50 ℃, and some steam penetrates into the foam beads during the pre expand process. The foam beads are relatively wet. After the foam beads are discharged from the outlet of the pre expander machine, due to the large temperature difference between the foam beads and the environment, the residual foaming agent and steam in the foam beads will soon condense into liquid, and the liquid foaming agent will dissolve into the polystyrene foam beads, The pressure inside the bubble quickly decreases, and there is a negative pressure (or part of the vacuum) inside. At this time, the bubbles appear soft, and are easy to deform. They can not make EPS foam products at all.

After ripening, on the one hand, it is dried, on the other hand, it allows air to penetrate into the interior of the foam beads to eliminate negative pressure, balance the internal and external pressure of the foam beads, make the foam beads round and elastic, ensure the expansibility of the foam beads and the fusibility between the beads during molding, so as to improve the quality of EPS products.

After understanding the mechanism of pre expand and ripening, if the thermal insulation effect of pre expand and ripening workshop in winter is poor, the temperature is low, the thermal expansion and cold contraction cause the beads shrink and collapse easily, and the bubble beads structure is damaged, then it can not rebound during ripening. If a lighter weight plate is made at this time, the plate is easy to shrink, cash, crack and become heavier. There is an optimum value for the general ripening temperature that is 18 ~ 22 ℃, and the air penetrates into the foam beads, while the pentane in the foam beads basically does not diffuse outward. When the temperature exceeds 22 ℃, the air infiltration rate increases and accelerates, and the outward diffusion rate of pentane also increases at the same time; On the contrary, if the temperature is lower than 20 ℃, the air infiltration rate is also significantly reduced and the ripening time is prolonged. Therefore, it is best to control the ripening temperature between 20 ~ 25 ℃; If the main production of light plate customers, the temperature of the ripening workshop can be appropriately increased to about 28. (the data is for reference only and shall be subject to the actual workshop conditions.)

We all know that in order to make the board light, the pre expander process must be light, which is theoretically feasible. However, combing the above mechanisms, we can explain why the lighter the foam is, the heavier the board is?

For example, a light plate:

1. First expanded: take one kind of pre expander machine as an example: it is found that it is heavy. In order to make the plate light enough, some workers will generally increase the whole body pressure to make the foam lighter. This is actually wrong. It's not that the higher the pressure, the lighter it will be. It depends on the situation. Light boards have two pre expander process. If first expander is too light, it is easy to destory the beads during the second expander. In this way, the board is heavy. Generally, the cylinder pressure shall not exceed 5.5kg, and the air inlet speed shall not be too fast, so that the material can be distributed evenly.

2. Second expander: EPS raw materials expanded should generally be placed in the ripening bin with an angle of no less than 20 ° and no more than 40 °. If it is lower than 20 °. At the same time, the oxidation time shall not be less than 4 hours, and then conduct second expander. In this way, the weight of the plate and the quality of the plate can be guaranteed. (the data is for reference only and shall be subject to the actual plate making.)

Therefore, if the temperature of the ripening bin is too low, especially in autumn and winter, a cold and rainy season may result from the fact that the insulation facilities of the foam plant are not good, and the air leakage is everywhere. The temperature of the workshop is almost the same as that outside, so the foaming agent in the foam beads is liquid and cannot be gasified and expanded, resulting in shrinkage of the foam particles and poor hand feel of the finished products. If you want to make a light board, you have to make it heavier. Therefore, in autumn and winter, we should strengthen the thermal insulation and heating of the silo workshop in order to make good products.