Home > Products > EPS Shape Molding Machine > High Quality Energy Saving Auto Vacuum Eps Foam Cornice Shape Molding Machine

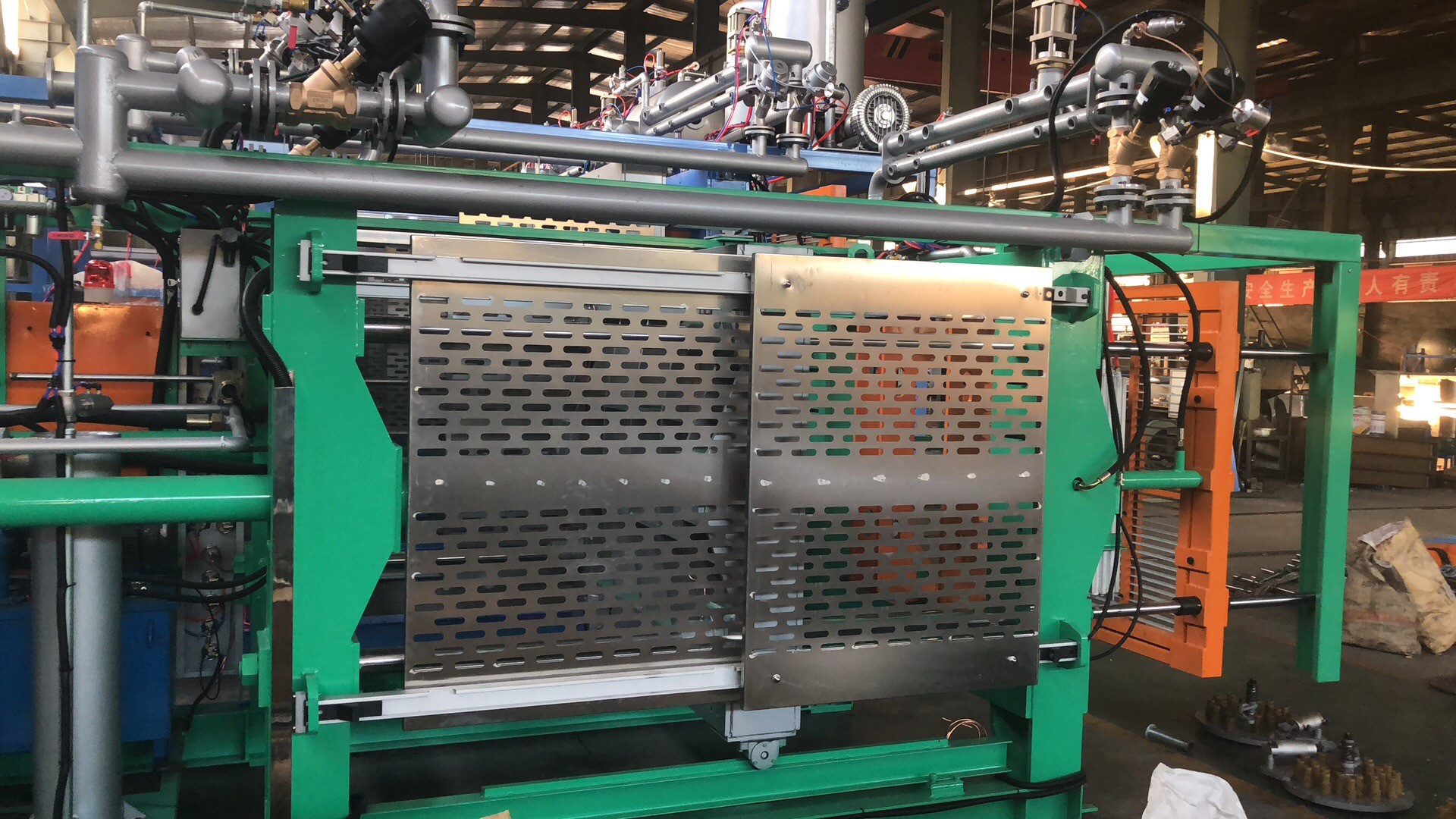

High Quality Energy Saving Auto Vacuum Eps Foam Cornice Shape Molding Machine

This machine adopts Vacuum system and hydraulic system with differential speed device, increase the speed of foam molding and shorten the cooling time, reduce product moisture content.

Description

1. Controlled by PLC and Touch screen

2. less energy consumption, high efficiency

InquirynowTechnical Date

|

Item |

LWS-1200E |

LWS-1400E |

LWS-1600E |

LWS-1750E |

|

|

Mould Dimension(mm) |

1200x1000 |

1400x1200 |

1600x1350 |

1750x1450 |

|

|

Max Produce Size(mm) |

1050x850x400 |

1250x1050x400 |

1450x1250x400 |

1600x1300x400 |

|

|

Stroke (mm) |

150-1350 |

150-1350 |

150-1350 |

150-1350 |

|

|

Steam |

Entry |

DN80 |

DN80 |

DN80 |

DN80 |

|

Consumption |

2.5~5kg/cycle |

4~6kg/cycle |

5~7kg/cycle |

6~8kg/cycle |

|

|

Pressure |

0.5~0.7Mpa |

0.5~0.7Mpa |

0.5~0.7Mpa |

0.5~0.7Mpa |

|

|

Cooling Water |

Entry |

DN80 |

DN80 |

DN80 |

DN80 |

|

Consumption |

45~130kg/cycle |

50~150kg/cycle |

55~170kg/cycle |

55~180kg/cycle |

|

|

Pressure |

0.3~0.5Mpa |

0.3~0.5Mpa |

0.3~0.5Mpa |

0.3~0.5Mpa |

|

|

Compressed Air |

Entry |

DN50 |

DN50 |

DN50 |

DN50 |

|

Consumption |

1.5m3/cycle |

1.8 m3/cycle |

2 m3/cycle |

2.5 m3/cycle |

|

|

Pressure |

0.5~0.7Mpa |

0.5~0.7Mpa |

0.5~0.7Mpa |

0.5~0.7Mpa |

|

|

Vacuum pump capacity |

230m3/h |

230m3/h |

280m3/h |

280m3/h |

|

|

Cycle time |

50~90s |

50~100s |

60~130s |

60~130s |

|

|

Power |

13kw |

14kw |

18kw |

18 kw |

|

|

Overall dimension(mm) |

5200*2200*4500 |

5300*2300*4600 |

5400*2400*4700 |

5400*2600*4800 |

|

|

Machine Weight |

5400kg |

6400kg |

7600kg |

8100kg |

|

Features

About Energy Saving Auto Vacuum Eps Foam Shape Molding Machine

Mechanical structure

1. It is welded by steel plate with 20-25mm steel plate. The welding adopts carbon dioxide protection welding. All the templates are treated by high temperature tempering, with high strength and high surface hardness.

2. All templates are CNC machining to ensure machining accuracy.

3. After the template gold is processed, the surface is sprayed with zinc to extend the service life of the whole machine.

Electrical control

1, all electrical components are famous brands to ensure the stability of the equipment, the touch screen shows the operating status of the machine's various processes, The interface is clear, easy to operate, and the program has multiple self-protection and alarm systems;

2.Through the steam pressure, the main steam pressure, demoulding, air cooling, pressurized feed are all using a remote pressure regulating system, the valve is opened and closed according to the set pressure ratio, easy to operate.

Feeding system

1. Adopting the structure of horizontal double rotating disc discharging barrel, there are 44-1" discharge ports, which can fully meet the requirements of customers with multiple products and multiple guns; Also vertical double material tank optional

2. In order to avoid uneven mixing of horizontal material, double-rotating discharge tray has the advantages of relatively small cross-sectional area of vertical barrel and good sealing.

3. Control of material position resistance switch Material alarm shutdown function, with pressure feeding, vacuum feeding, intermittent feeding function.

Steam system

1. Adopting Japan Yoshitake steam pressure reducing valve, steam flow and pressure is stable.

2. Use Japan SMC's electric proportional valve and the US MAC's high-frequency solenoid valve to control the mold steam inlet pressure.

Vacuum system

1. Simultaneously configure vacuum tank and condenser to increase the vacuum volume.

2. The top of the vacuum bucket is equipped with a detachable sprinkler device, which increases the vacuum condensation ratio by spraying the cooling water, thereby improving the vacuum suction efficiency.

3. Make the equipment truly achieve the effect of cooling water vaporization and heat absorption, and the product has low water content.

Application

-

Ship 1 Container EPS Machine to Algeria

2022-03-21

-

Excellent EPS mold supplier in China

2022-03-21

-

Foam Cutting Machine cost performance is very important

2022-03-21

-

Ship EPS Beads Machine to Indonesia

2022-03-21

Related News

Products Recommended

THE LEADER OF EPS MACHINERY

Contact us- EPS Pre-Expander

- EPS Shape Molding Machine

- EPS Block Molding Machine

- EPS Cutting Machine

- EPS Recycling Machine

- EPS Mold

- EPS 3D Production Line

- Assistant Equipment & Spare Parts

- Vacuum Forming Machine

OUR PRODUCTS

- About us

- Professional service

- Q&A